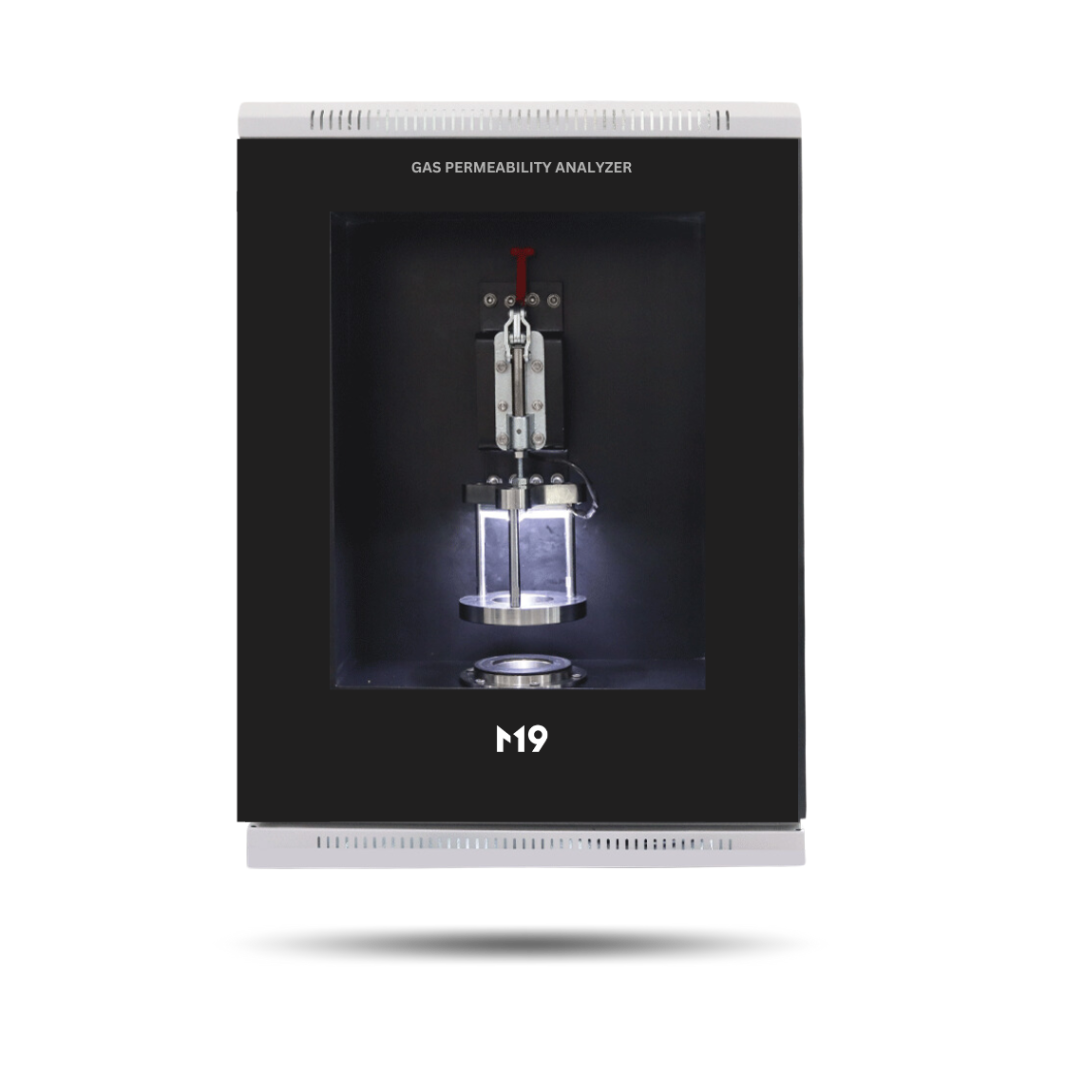

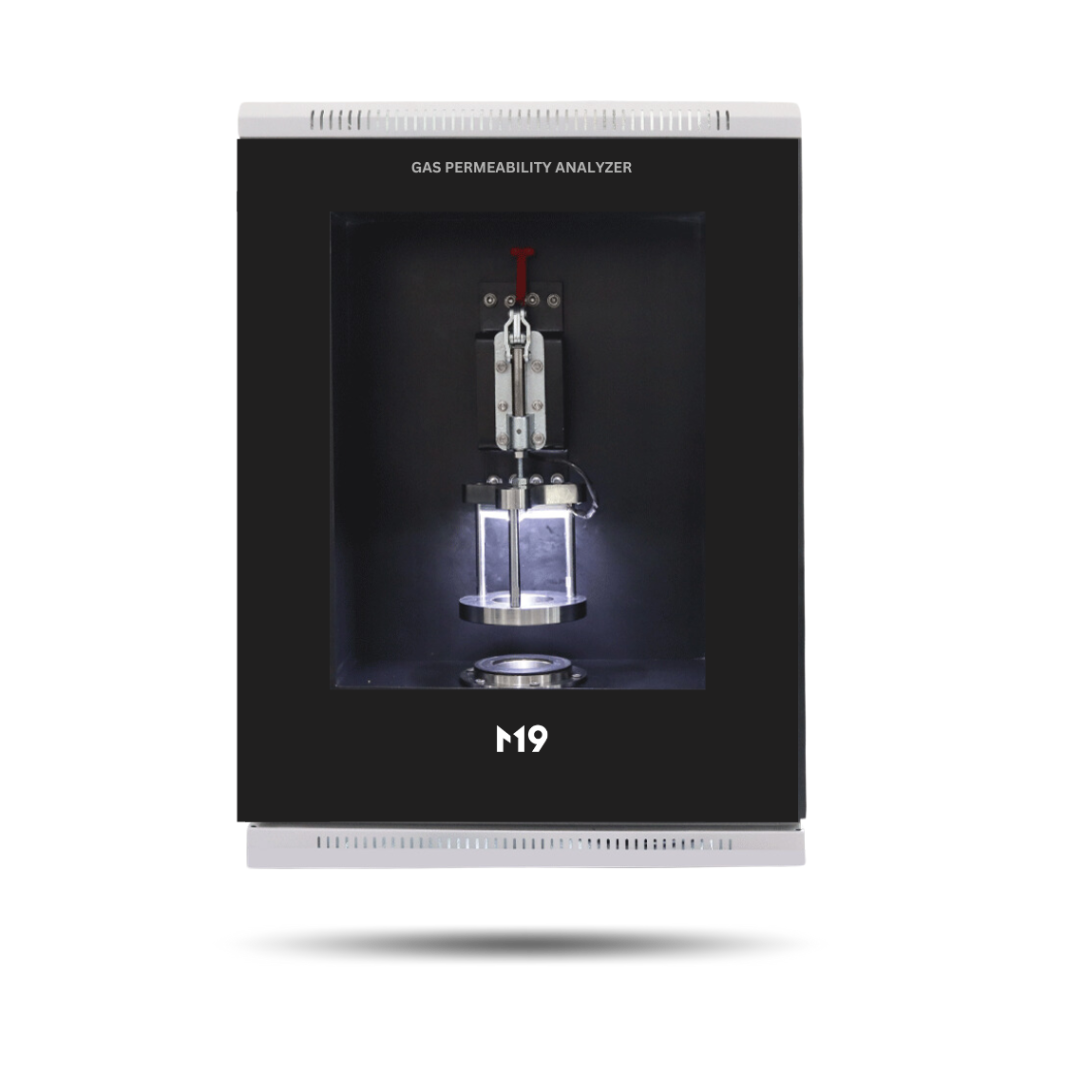

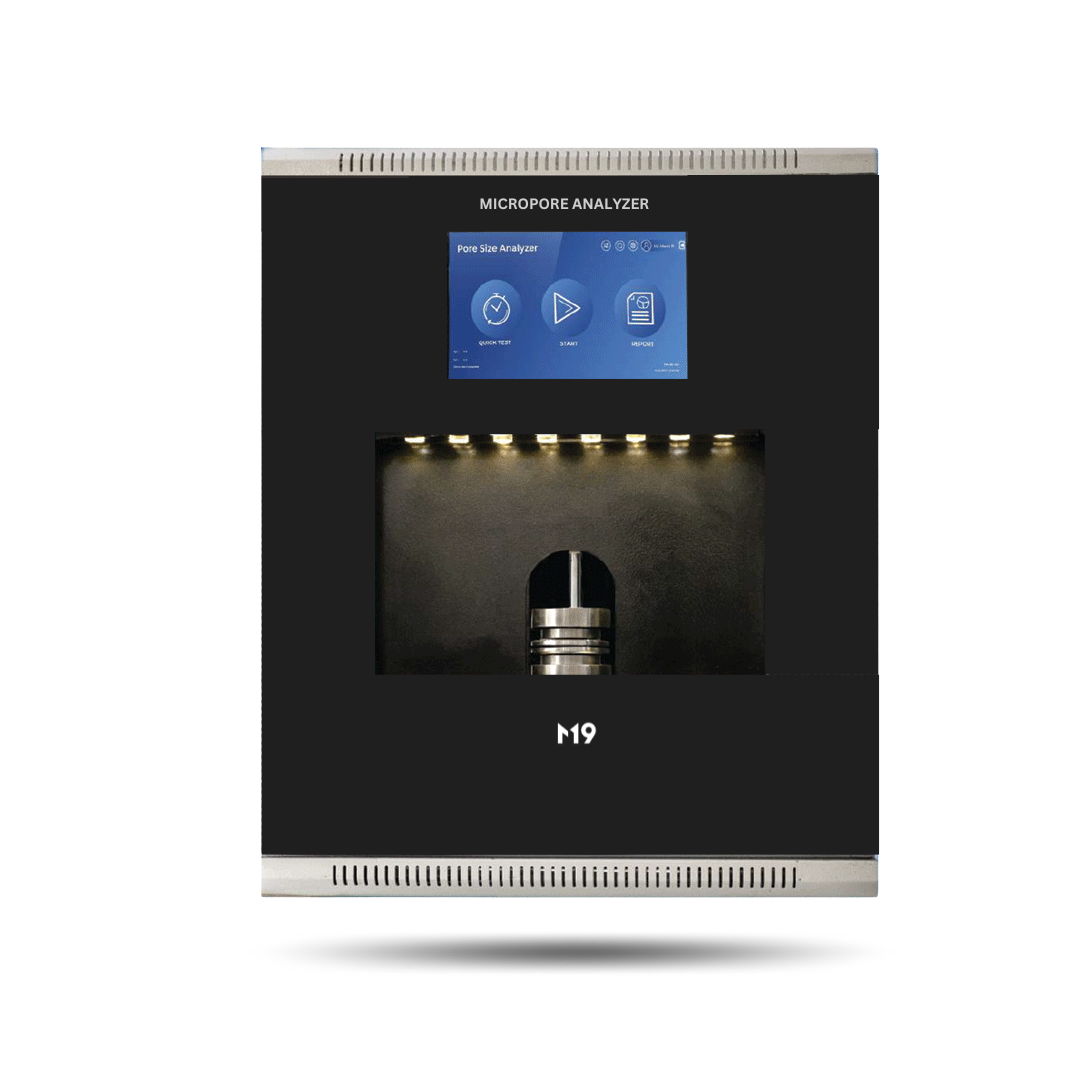

Air Permeability Analyzer

ASTM F316, ASTM D6767

- Request Quote

- Download Brochure

- Learn More

Stay up-to-date with the latest news, trends, and insights delivered directly to your inbox.

Subscribe

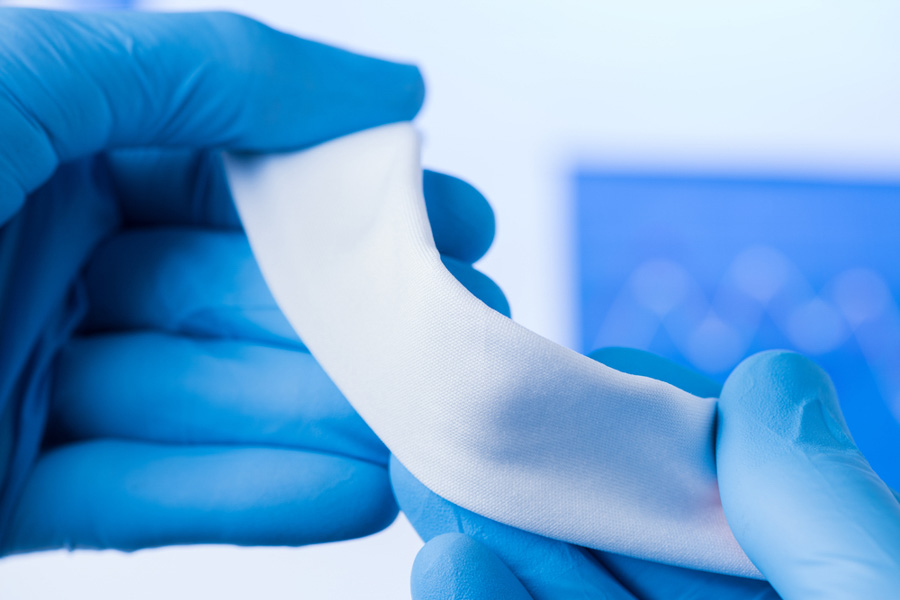

Ultra-high precision testing throughout all technical fabrics and coated/ laminated material applications in Body Coveralls, Bio Suits, hazmat Suits, Protective textiles in medical applications

For 100% bacterial/viral resistance masks, The M19 lab assists in characterizing membrane-based filters used in respirators and half/full masks.

Assisting fabric manufactures and suppliers to authenticate/validate of fabric raw materials used in various protective/ bacterial resistance applications in medical settings.

At the forefront of the smart textile community, healthcare and sustainability are the two crucial objectives targeted by researchers. The development of such powerful devices has been driven by innovative fabrications of breathable, skin-conformable technologies through the use of functional and programmable materials and device structures. This Perspective focuses on the current smart textiles available in the research field, categorized into personalized healthcare, including diagnostics and therapeutics, and sustainability, including energy harvesting and conservation─personalized thermoregulation. These categories are further broken down into their platform structural technologies and performances.

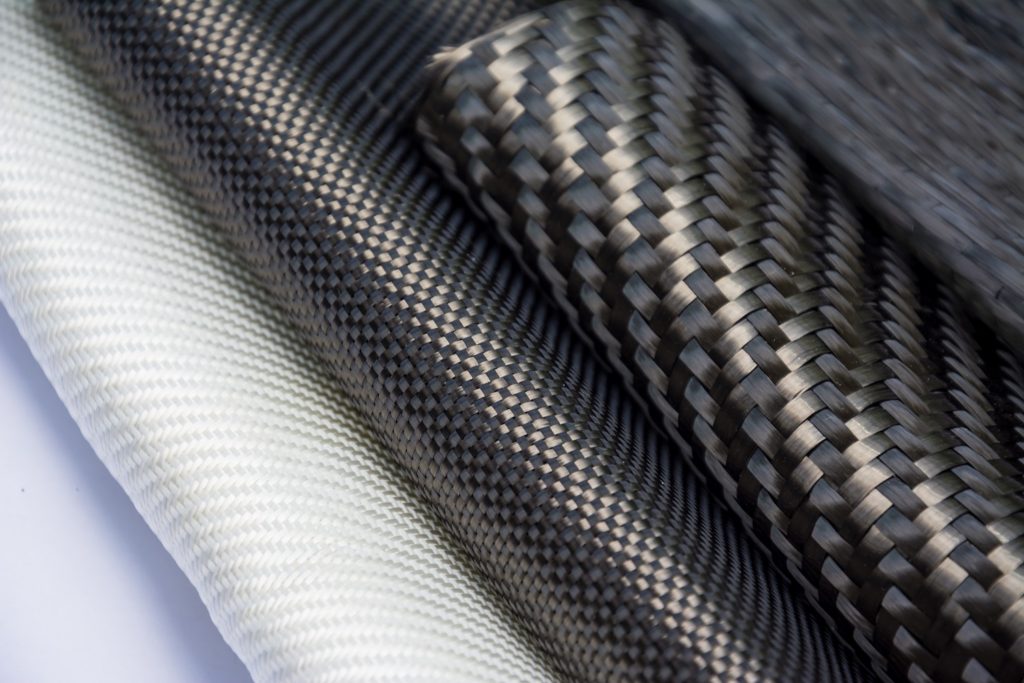

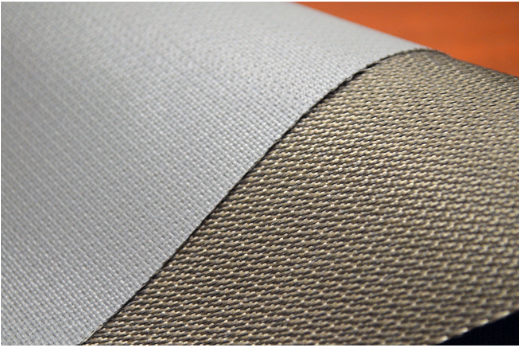

The coating and finishes are used in to improve the appearance and performance of dyed fabric in textile industry. Finishing is done through mechanical, thermal, and chemical processes. Chemical finishes are generally applied as an aqueous solution or emulsion that impregnate the fibers. On the other hand, textile coatings involve the application of a viscous liquid at the surface of the fabric, which will not only cover the yarns but also the space between them. The modern applications of nano-enabled coatings and finishes include antibacterial wound dressings, odour-free socks and shoe insole, stain-resistant, crease-free, and fast drying clothing, water-repellent yet breathable raincoats and sleeping bags and hydrodynamic swimsuits.

Coated fabrics are synthesized by carrying out the surface treatment of homogenous polymeric materials and different textile forms such as woven, knit or non-woven that are utilized as substrate. The polymeric coating should adhere to the textile material, maintaining the required thickness and cured subsequently. Coating a fabric has several advantages, for instance, protecting the textile from atmospheric damage such as UV rays or harsh weather conditions, proofing the materials from water and moisture or even altering the macro-mechanical behaviour of fabric like tensile or tear according to the sine qua non.

Biohazard and NBC(Nuclear, biological and chemical ) suits have two chief functions, gas or vapor protection and splash protection. Gas protection suits are specifically designed to shield wearer from anything except radiation. They are totally encapsulated, over-inflated and worn with self-contained breathing apparatus(SCBA) to allow the wearer to breath easily even in completely closed system. Their level of protection is determined according to their permeation rate, breakthrough rate and degradation. Their permeation rate should be low to block or abate the contagions from moving through the suit material. Their breakthrough time, which refers the time taken for contagions to completely permeate through the suit, should be greater. The materials of these suits shouldn’t degrade when they come in contact with the contagions.

Natural and synthetic material are used to prepare health care hygiene products. The fiber used in medical textile –Natural fiber (cotton, silk, etc.) and synthetic fibers (poly-ester, viscose, polyamide, polypropylene, carbon, glass) Bandages, plaster, wound dressing products are called non-implantable medical textile product are prepared from textile fibers. Sutures and ligaments, vascular grafts, artificial skin, artificial cornea, contact lenses and dental biomaterials implant are also prepared from textiles. A lot of sanitary and hygiene products are also prepared from textiles. Surgical mask, drapes and clothes, surgical gowns, surgical caps, gloves, baby dippers and sanitary napkins are directly produced from textile materials.

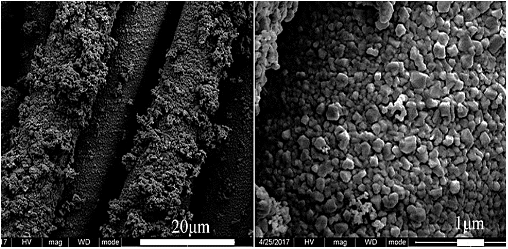

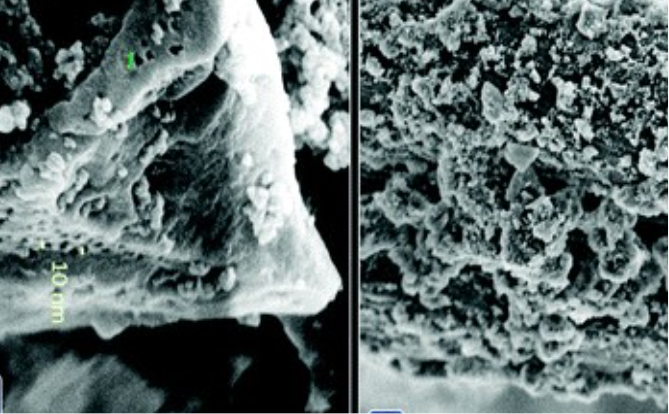

Smart textiles consisting of cotton, Cu-BTC MOF and oxidized graphitic carbon nitride, g-C3N4-ox, nanospheres were synthesized and tested as nerve agent detoxification media and colorimetric detectors. Combining Cu-BTC and g-C3N4-ox resulted in a nanocomposite (MOFgCNox) of heterogeneous porosity and chemistry. Upon the deposition of MOFgCNox onto cotton textiles, a stable fabric with a supreme photocatalytic detoxification ability towards the nerve gas surrogate, dimethyl chlorophosphate, was obtained. The detoxification process was accompanied by a visible and gradual color change, which can be used for the selective detection of chemical warfare agents and for monitoring their penetration inside a protective layer. These smart textiles adsorbed almost 7 g of CWA surrogate/its detoxification products per gram of Cu. The superior performance was linked to the high dispersion of the MOF crystals on the fibers, and a specific texture promoting the availability of the active copper centers.