Acoustic Resistance Analyzer

ASTM F316, ASTM D6767

- Request Quote

- Download Brochure

- Learn More

Stay up-to-date with the latest news, trends, and insights delivered directly to your inbox.

Subscribe

Sintered metal filters are also commonly used in oil filtration applications to remove contaminants from oil. In this application, the filter is made by compressing metal powder into a solid block and then sintering it at high temperatures to create a porous structure. The oil flows through the porous structure, while contaminants are trapped on the surface or inside the filter.

Cartridge filters are commonly used in oil filtration applications to remove contaminants from oil. They are made up of a cylindrical housing with a filter element inside. The filter element is typically made of a pleated paper or synthetic material that traps contaminants as the oil flows through it.

Automotive filters are a type of oil filter used in automobiles to remove contaminants from engine oil. They are typically made up of a metal housing with a replaceable filter element inside. Automotive filters can be designed to remove a wide range of contaminants from engine oil, including dirt, dust, and other solid particles. They can also be designed to remove water or other types of contaminants from the oil.

Cartridge filters have application in various fields. For example filtration of lubricant oil or fuels in engines of automobile, cold sterilization of a beverage or injectable solute, ultra-decontamination of chemical and rising waters in electronic component manufacture, removal of particles susceptible to clog an ink jet printer, cleaning of nuclear power plant liquids etc.

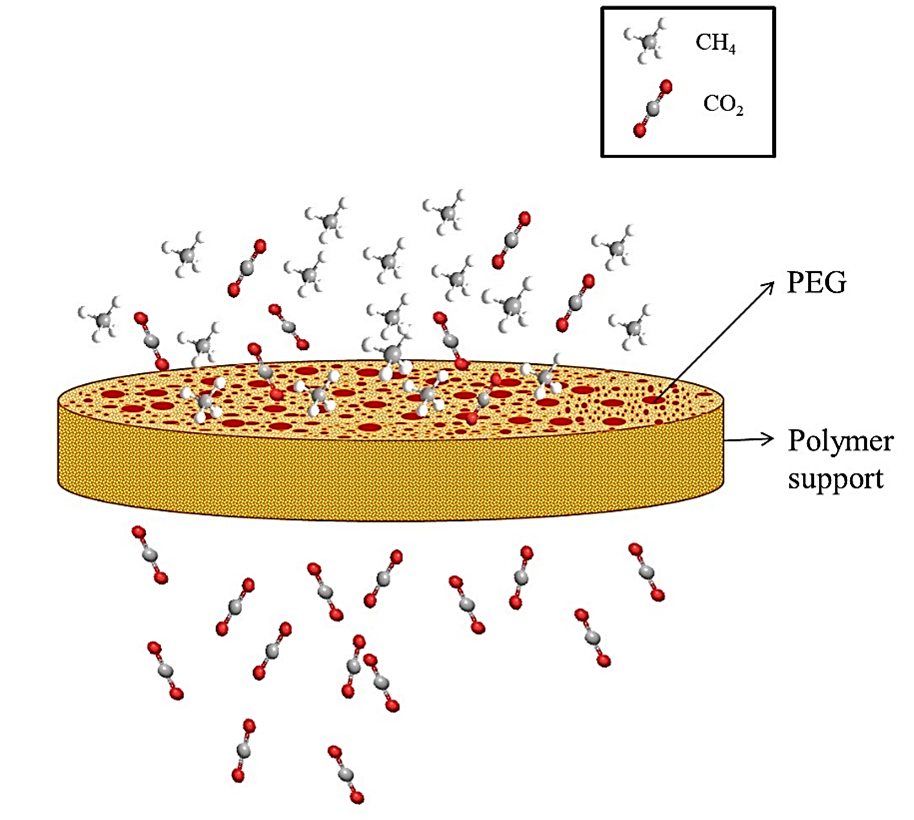

Membrane technology is among many techniques for CO2 gas separation. The cellulose acetate (CA) membrane is a widely used polymeric membrane for gas separation, including CO2 and CH4 gases.

The development of advanced adsorbents with high capacity, fast rate, and easy regeneration has great practical application value. In this paper, polystyrene-polymaleic(anhydride) (PSMM-NH2) hollow microspheres with a high density of amino groups are prepared and used for the efficient adsorption of anionic dyes with the maximum adsorption amount for acid red as high as 951.1 mg g−1.

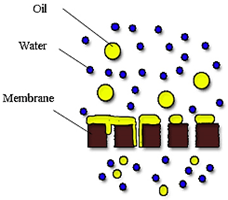

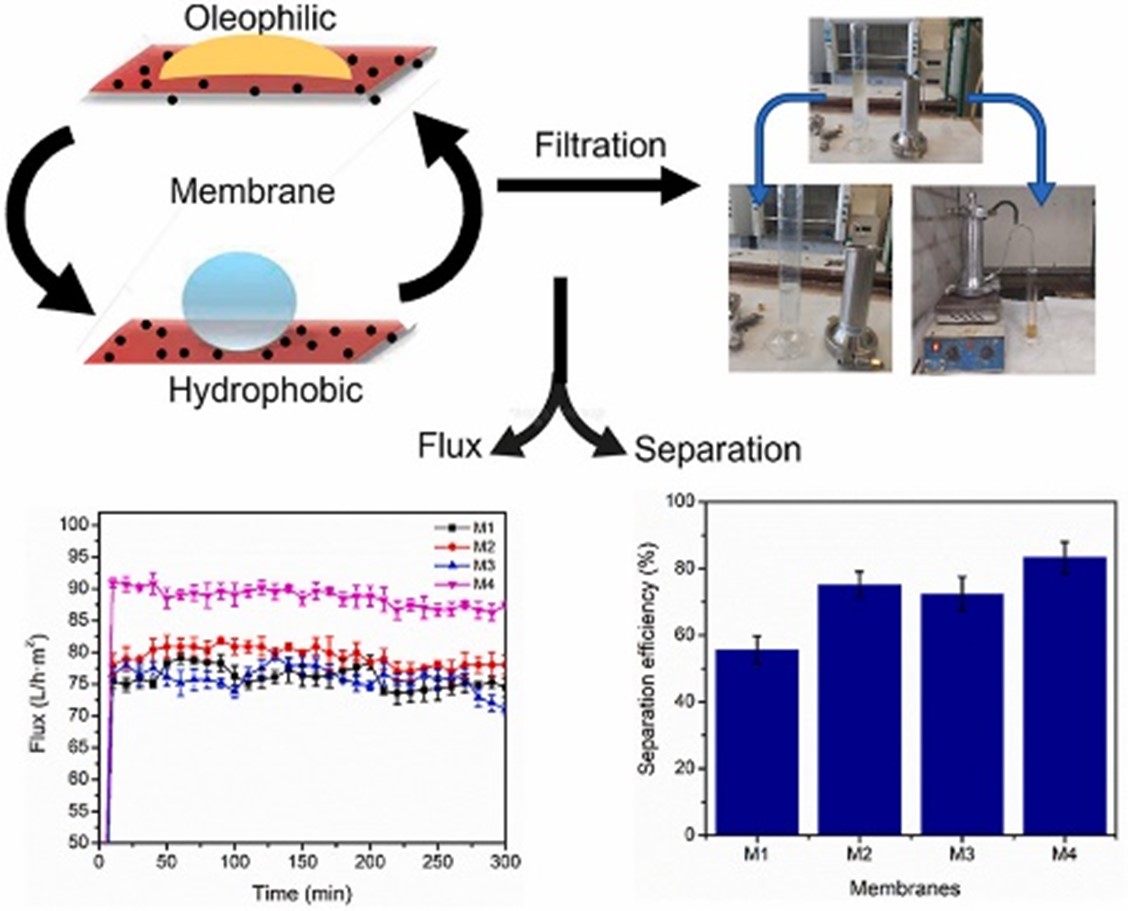

In various industrial processes water comes into contact with several pollutants, like hydrocarbons, hazardous chemicals, sewage sludge from boilers, cooling towers, and heat exchangers, and is not reusable.

Oil spillage and industrial discharge of oily wastewater threaten the health of the human beings and the environmental life. To perform oil cleaning from the water bodies, several physicochemical methods have been employed.

Sintering is a process of the metallurgy of filter with different metals and alloys (aluminium, copper, nickel, bronze, stainless steel, titanium etc.) in powder form.