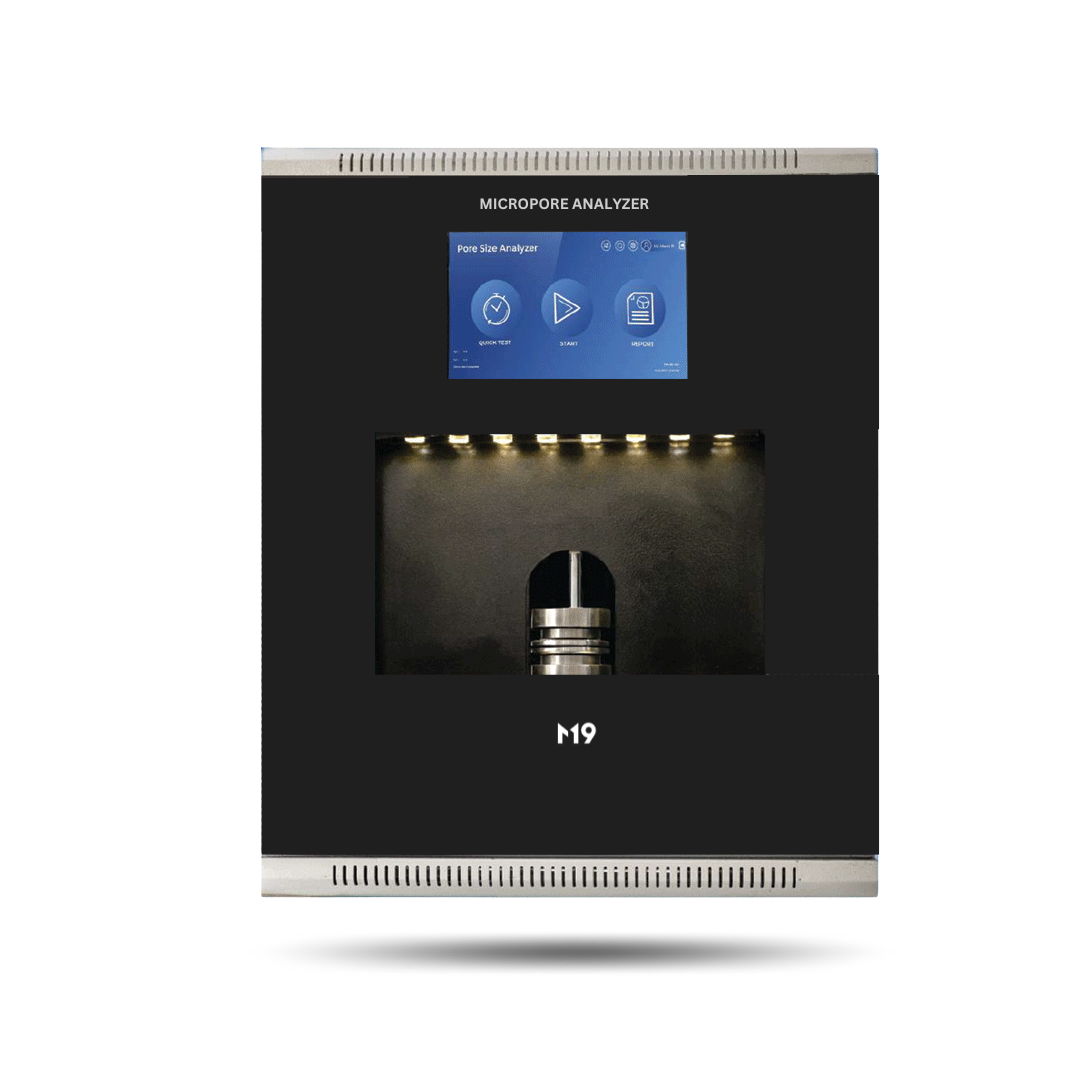

Integrity Analyzer

ASTM F316

- Request Quote

- Download Brochure

- Learn More

Stay up-to-date with the latest news, trends, and insights delivered directly to your inbox.

Subscribe

Ultra-high precision testing throughout all types of membrane filters across cross-flow, microfiltration, nanofiltration, ultrafiltration & reverse osmosis applications.

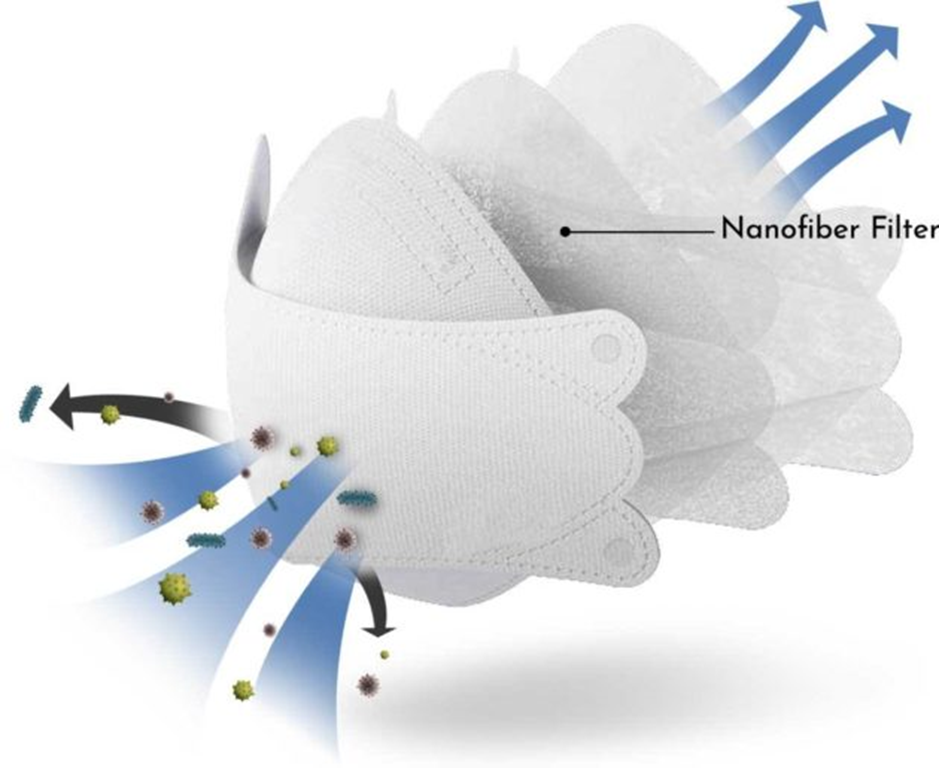

Testing spunbond, meltblown, electrostatic, glass fiber, pleated and various configurations across various air filtration products including HEPA.

Syringe filters are widely used in the pharmaceutical industry for a variety of applications, including filtering out particulates or microorganisms from pharmaceutical solutions before they are administered to patients.

The bag filter is a device used to improve quality of air in pharmaceutical production and other similar areas.In pharmaceutical production drugs like hormones, vitamins, antibiotics etc. generates lot of dust during different processes such as screening, blending, mixing, drying, granulating, tableting, compression, packaging etc. which causes air pollution and contamination.

Natural and synthetic material are used to prepare health care hygiene products. The fiber used in medical textile –Natural fiber (cotton, silk, etc.) and synthetic fibers (poly-ester, viscose, polyamide, polypropylene, carbon, glass) Bandages, plaster, wound dressing products are called non-implantable medical textile product are prepared from textile fibers.

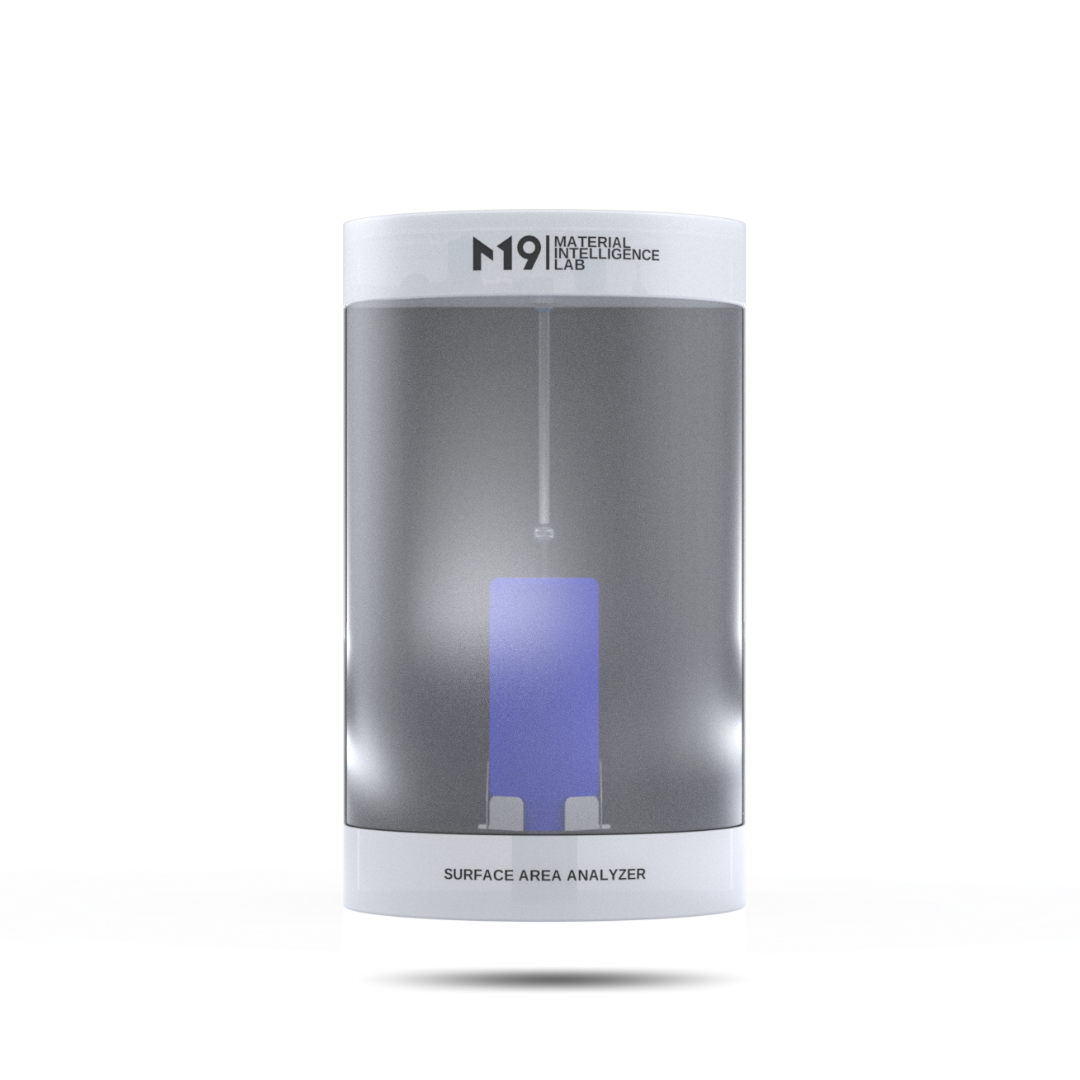

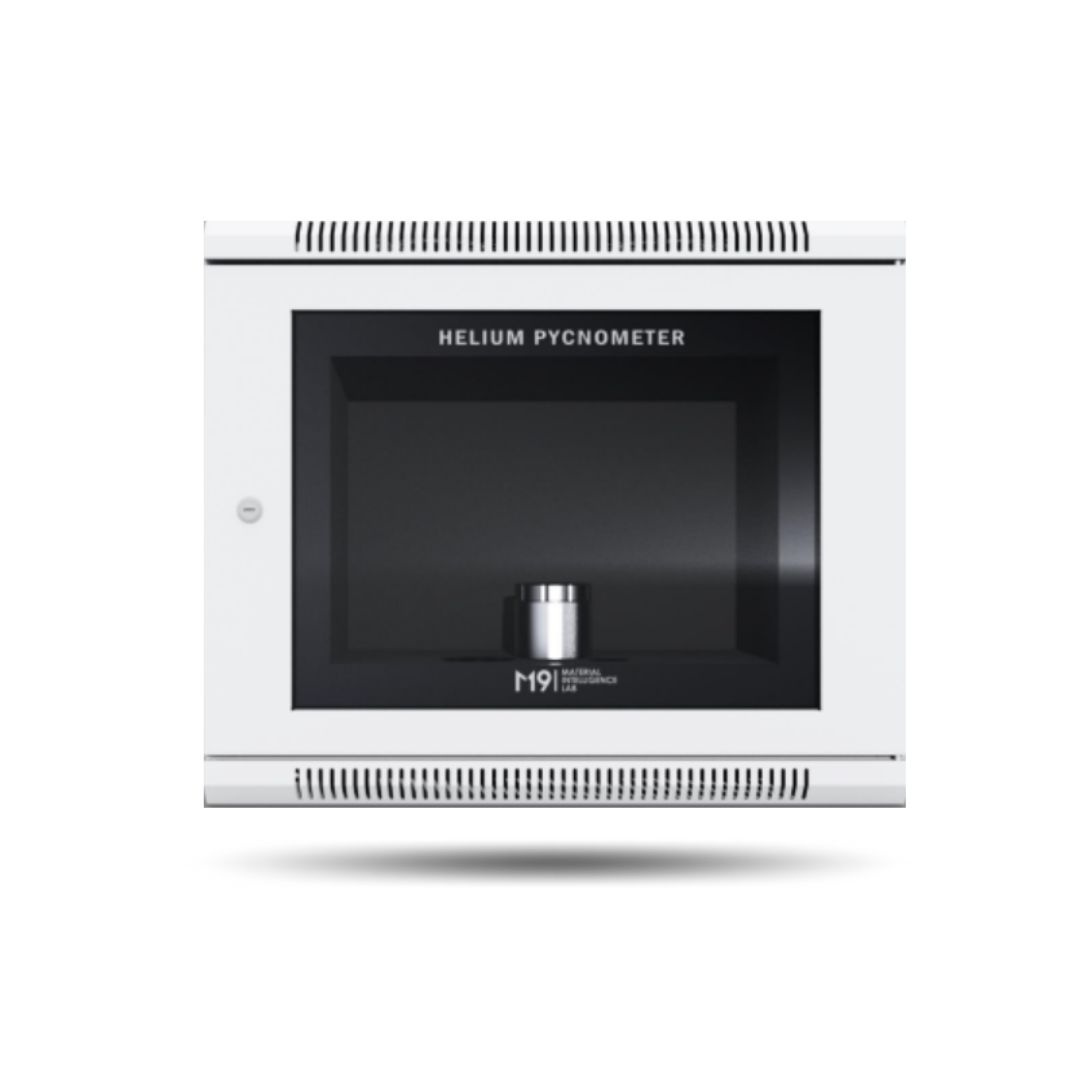

Filters of different pore ratings and material are extensively used in the pharmaceutical industry for various applications like purification, pharmaceutical and bio-pharmaceutical operations such as sterile filtration and protein purification, analysis of drug products.

Integrity testing ensures the accuracy of filtration media and validates that filtration media was not compromised before or during filtration. This is very important if a filter is being used as a final sterile filtration.

A facemask is a loose-fitting, disposable device that creates a physical barrier between the mouth and nose of the wearer and potential contaminants in the immediate environment.

Pharmaceutical industry requires different filtration methods depending on type of chemical solution that is being processed.