Micropore Analyzer

ASTM F316, ASTM D6767

- Request Quote

- Download Brochure

- Learn More

Stay up-to-date with the latest news, trends, and insights delivered directly to your inbox.

Subscribe

Ultra-high precision testing throughout all Pleated, Membrane-based, Metallic Mesh, Sintered metal type of Cartridge Filters. All kinds of Cartridge Filters used in separation sciences across microporous, microporous & nanopores are covered at the M19 lab.

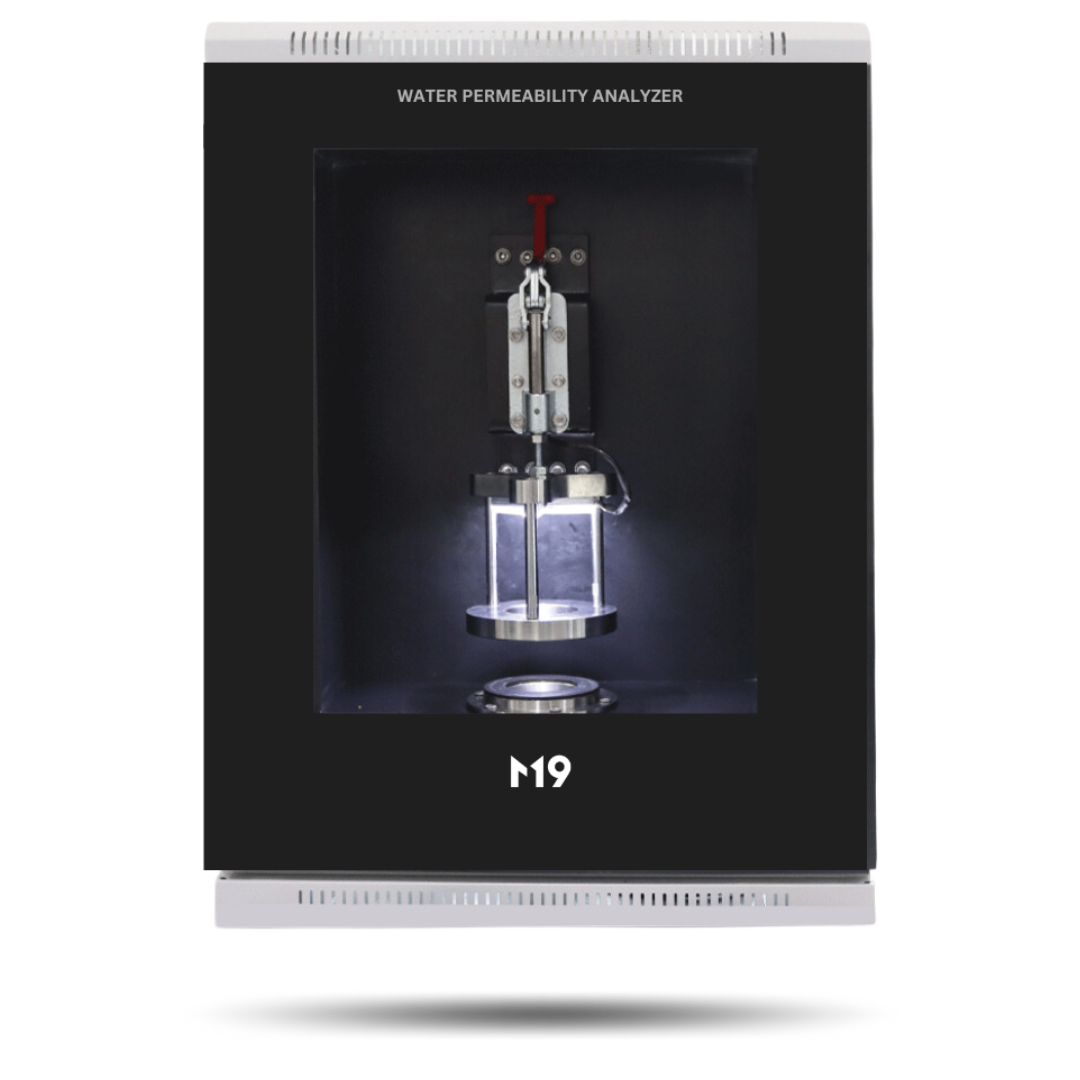

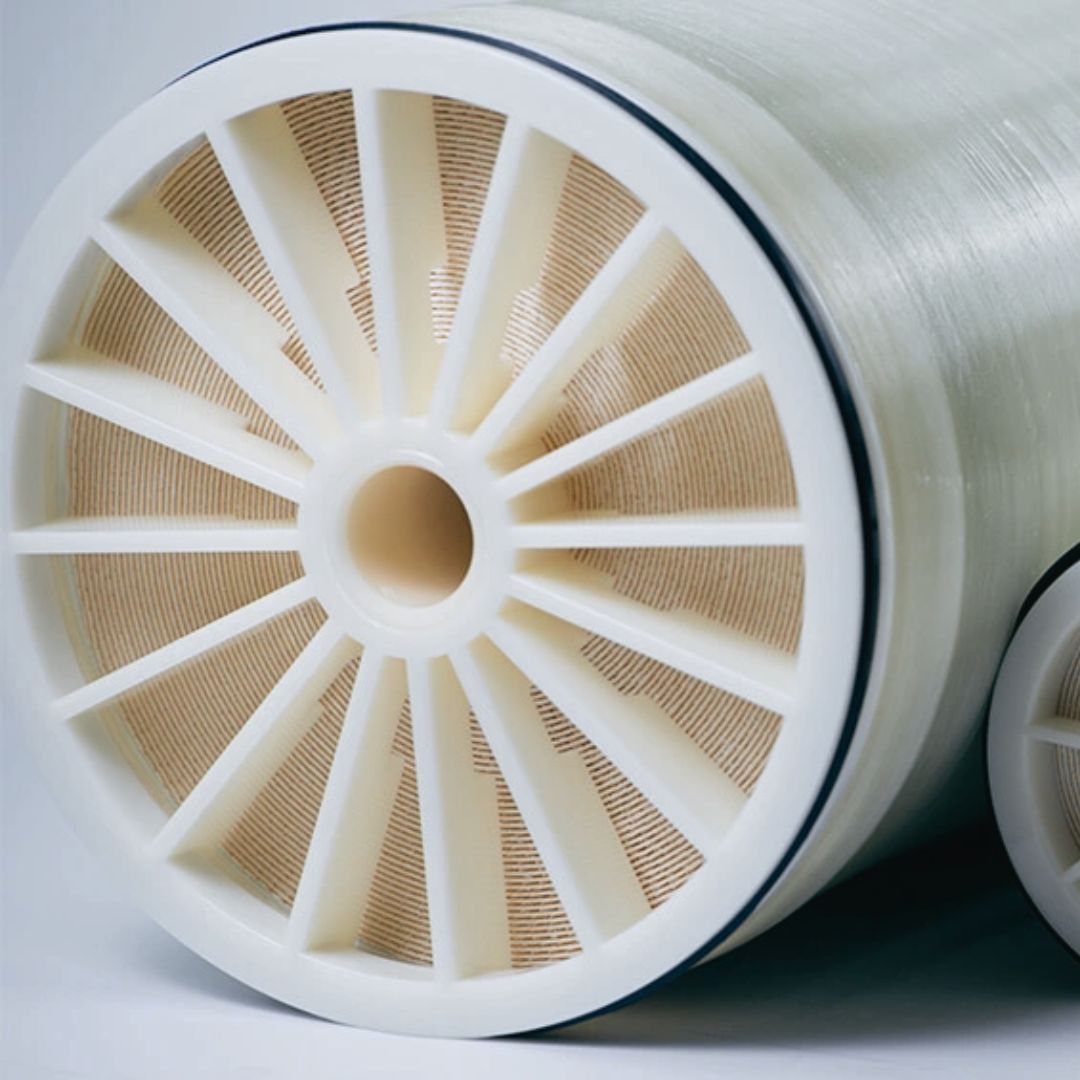

Reverse Osmosis Filter System is one of the strongest, most effective filters for drinking water. M19 lab analyzes high-performance membranes that remove 99% of the most dangerous contaminants in the water, including heavy metals, pesticides, chlorine, or other chemicals.

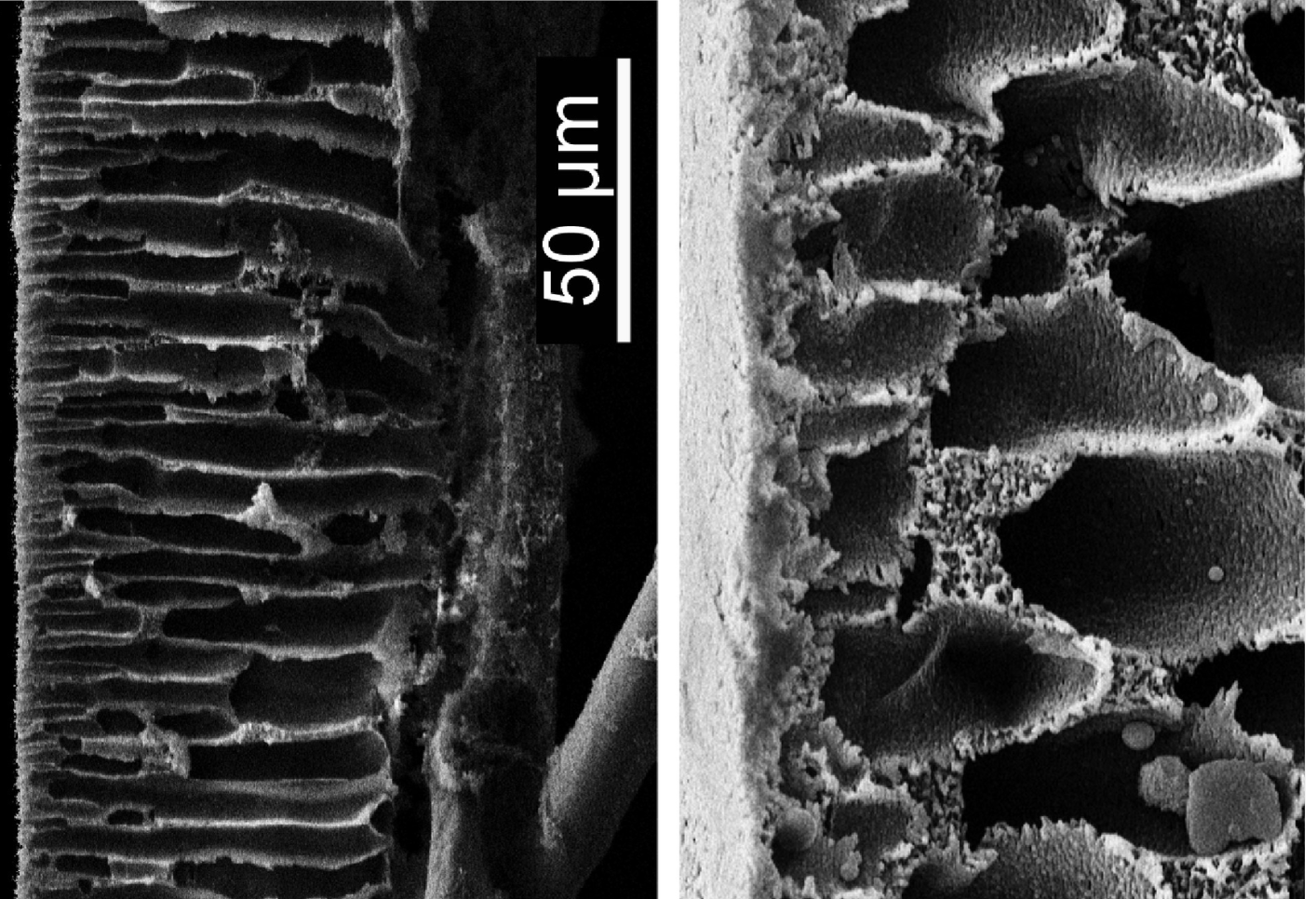

A Cartridge Filter is a piece of Tubular Filtration Equipment that can be used across various industries for an array of filtration requirements. A Cartridge is encased within a housing or a casing and used to remove unwanted particles, pollutants, and chemicals from liquids.

Activated carbon filters, also known as activated charcoal filters, are made up of small porous sponges or granule powder that have been processed to trap impurities. It is first injected with heat or steam to increase the carbon’s surface area. The activation process opens up more pores which allow carbon to absorb a wider range of contaminants. The carbon particles have a large surface area, which allows them to be exposed to as many active sites in the filter media as possible.

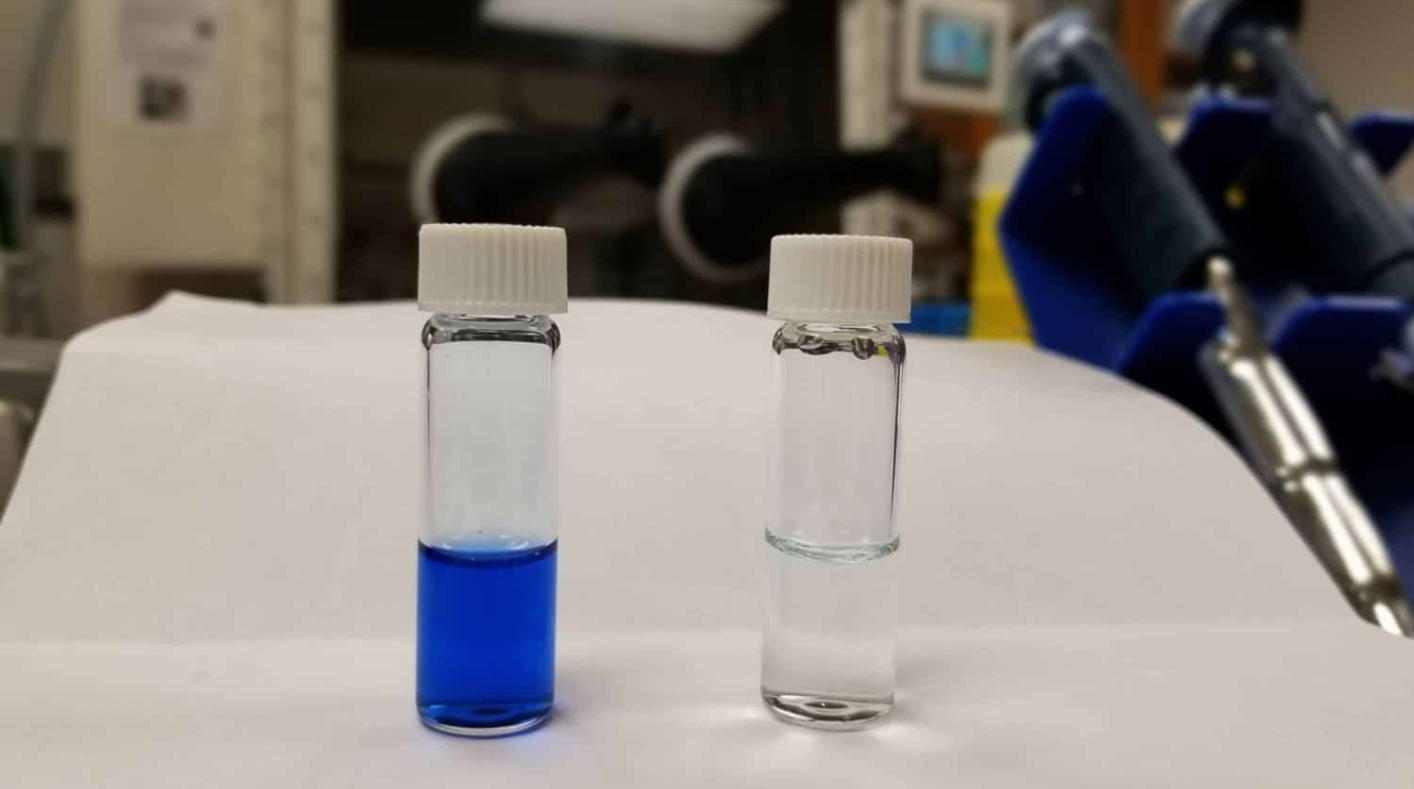

Contamination of wastewater with dye is a serious environmental problem. The main sources of contamination are textile factories, food, paper and printing products and vehicles productions. Different methods are used for the removal of dyes from wastewater such as adsorption, oxidation process, photocatalyst, biological decolourization and membrane separation technology. Membrane separation technology is used due to its advantages such as, convenient to operate, less space required, high elimination efficiency, no additional chemicals required etc.

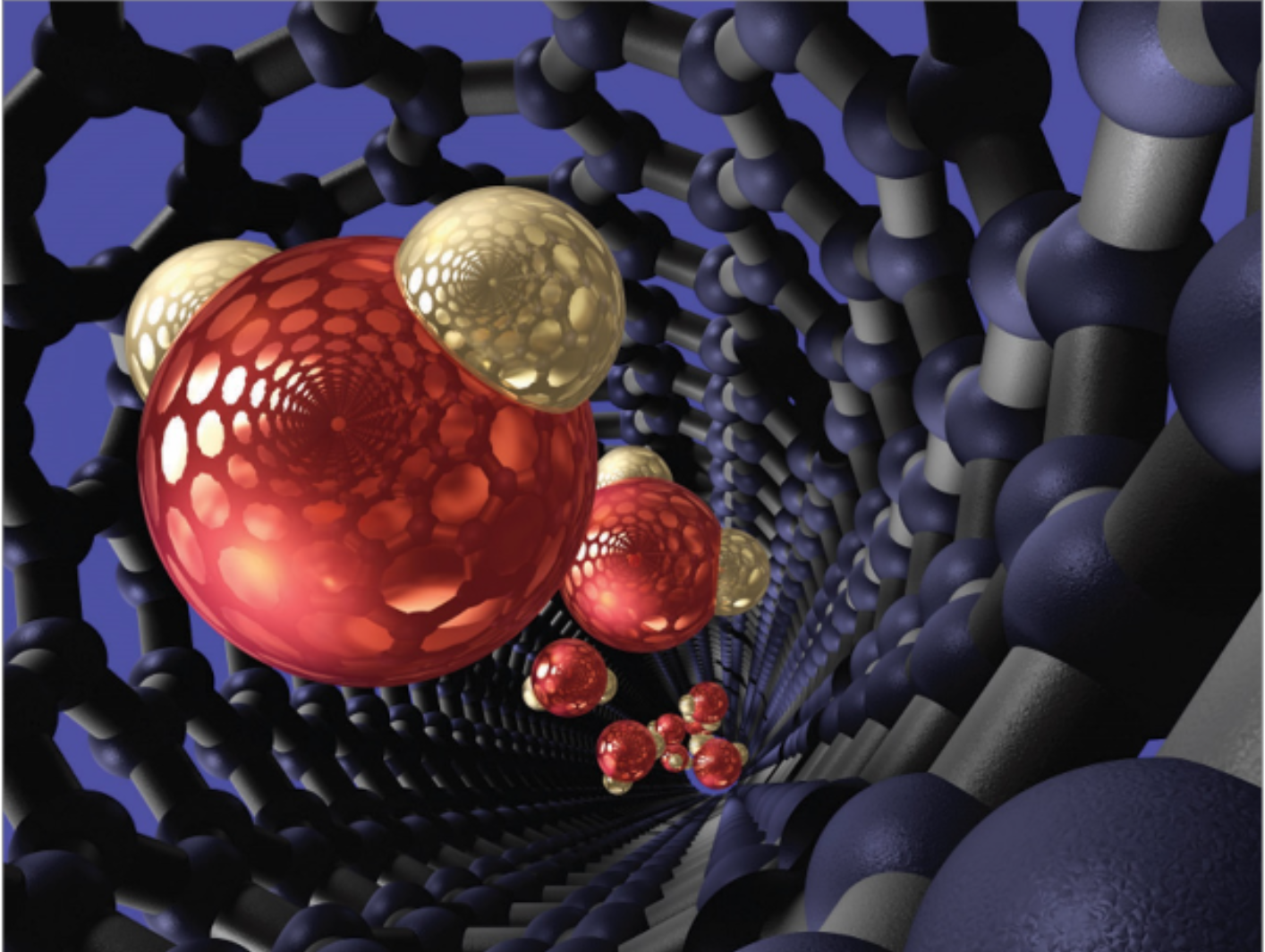

A technology uses acoustics rather than pressure to drive water through carbon nanotubes to perform filtration. Water enters the device and first contacts the filter matrix, which can be made of polymer, ceramic or metallic compounds, as per requirements. Carbon nanotubes within the matrix allow only water molecules to pass through, blocking larger molecules and contaminants.

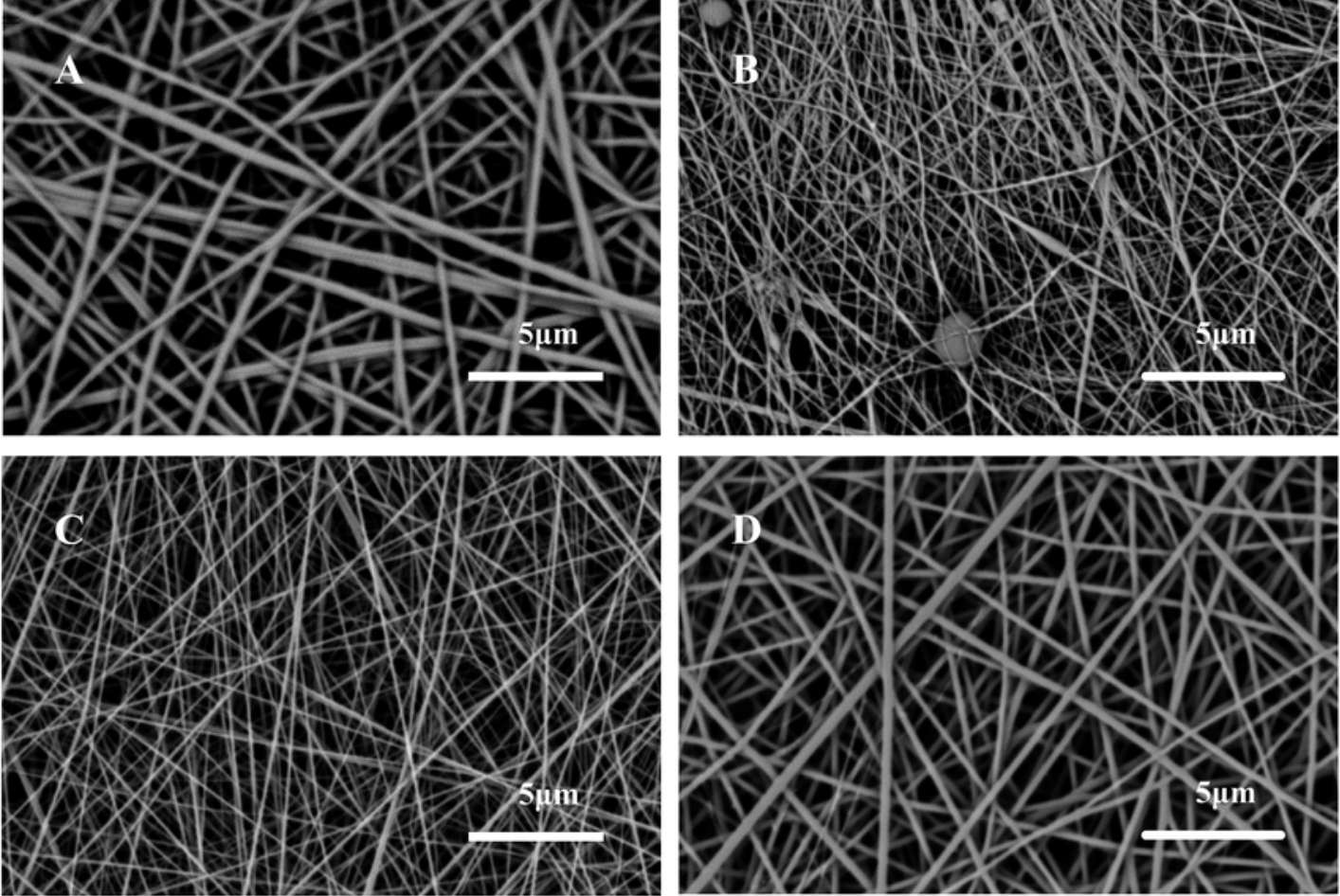

Recent advances in water filtration using electrospun nanofibrous membranes focus on improving the membrane surface functionality by either physical coating or chemical grafting pathways to introduce a variety of functional groups and meet specific requirements. Electrospun polyacrylonitrile nanofibrous (PAN NF) membranes are modified to enable the removal of bacteria, viruses(the typical size range in tens of nanometres) as well as heavy metal ions. Bacteria can be removed by size exclusion through adjusting the membrane pore-size.

The presence of bacteria, especially E coli is the main indication of fecal contamination of water, that causes water-borne diseases, severely impacting the health worldwide. Recent studies have shown that nano-silver deposition on commercial polypropylene water filter is a mean to improve its microorganism removal effectiveness.

Forward osmosis is a concentration driven process, which utilizes the osmotic pressure difference across a selectively permeable membrane for the transport of water. The potential application of Forward osmosis (FO) in wastewater treatment, water purification and sea water desalination has received intensive research to produce an optimized FO membrane that can produce high water flux compare to commercial RO membranes.